Choosing the right furnace and ensuring proper installation is vital for maintaining a comfortable and efficient home environment. Understanding the furnace installation process can help homeowners feel confident in their choice and aware of what to expect during this important service.

Understanding the Basics of Furnace Installation

Furnace installation involves several crucial steps to ensure the system functions correctly and efficiently. The process begins with selecting a furnace that matches the size and heating requirements of your home. Proper sizing is essential to avoid underperformance or excessive energy consumption.

Once the appropriate furnace is chosen, the installation process includes setting up necessary components such as ductwork, electrical connections, and the exhaust vent. Precise placement of the furnace is crucial to ensure adequate air flow and heat distribution throughout the home. Additionally, our professionals ensure that the combustion process is safe and efficient to prevent issues like carbon monoxide leaks.

During installation, considerations such as fuel type, efficiency ratings, and compatible thermostat systems are evaluated to optimize the overall performance of the furnace. Our specialists focus on maintaining safety and following local building codes to protect residents and the property.

Proper installation sets the foundation for a furnace’s lifetime performance and energy efficiency. It requires attention to detail, technical expertise, and adherence to safety protocols, making professional installation an essential step for any homeowner.

Selecting the Right Furnace for Your Home

Choosing the right furnace involves assessing various factors that influence both performance and efficiency. The climate in your area, the size of your home, and your existing system are all critical considerations. Start by evaluating the energy efficiency of different furnace models, which can significantly impact your heating bills.

Here’s a list of factors to consider when selecting a furnace:

- Fuel Type: Consider whether a gas, oil, or electric furnace best suits your energy needs and availability. Each type has unique features and cost implications.

- Efficiency Ratings: Look for units with high Annual Fuel Utilization Efficiency (AFUE) ratings to ensure lower operating costs.

- Size and Capacity: Choose a furnace sized appropriately for your home to guarantee optimal heating without wasting energy.

- Compatibility with Existing Systems: Ensure the new furnace is compatible with your existing ductwork and thermostat.

Comparing different furnace types and their efficiencies will guide you in making an informed decision. Balancing upfront costs with long-term savings and performance ensures you choose a system that fits your needs and budget.

The Role of Air Ducts in Furnace Efficiency

Air duct maintenance plays a significant role in the overall efficiency of your furnace system. Clean, well-maintained ducts ensure that heated air moves smoothly and effectively throughout your home. Regular air duct cleaning can prevent blockages and leaks that reduce heating efficiency.

Dirty ducts can restrict airflow, causing your furnace to work harder and less efficiently. This increased strain can lead to higher energy costs and even potential damage to the furnace over time. Moreover, neglected ducts can harbor dust, allergens, and other contaminants that affect indoor air quality.

Maintaining the condition of your ducts includes regular inspections and cleaning. Addressing any leaks or damages promptly can enhance the system’s performance. Our technicians recommend scheduling an annual duct cleaning to maintain optimal performance and air quality.

Air ducts are vital to heating systems, serving as the channels through which treated air is distributed. Ensuring these channels are clean and unobstructed is critical for maintaining the efficiency and longevity of your furnace.

Pre-Installation Assessment: What Our Technicians Do

Before proceeding with furnace installation, a pre-installation assessment is crucial to ensure the project runs smoothly. Our technicians conduct a comprehensive evaluation of your home to understand its unique heating needs.

The assessment process includes:

- Evaluating Heating Needs: Technicians assess your home’s size, insulation, and window efficiency to determine the correct furnace size and model.

- Inspecting Ductwork: Existing ducts are examined for any blockages or damage that could impair system performance. Necessary repairs or replacements are addressed.

- Checking Ventilation: Ensuring proper ventilation prevents hazardous buildup of gases and makes the heating system more efficient.

- Assessing Fuel Source: The availability and suitability of natural gas, oil, or electricity are reviewed to decide the best fuel type for your new furnace.

The pre-installation assessment ensures all factors are aligned for a successful installation. It helps identify potential issues that could disrupt the installation process. Our technicians thoroughly evaluate your new furnace to ensure that it operates optimally and safely.

Detailed Installation Process

The furnace installation process involves several methodical steps to ensure a successful setup. Our technicians begin by preparing the installation area, ensuring proper space for the furnace and clearances for ventilation. Correct positioning is essential for optimal air distribution and safety.

Here’s an overview of the typical installation steps:

1. Removing the Old Furnace: If replacing an existing unit, technicians carefully disconnect and remove it, taking care to manage gas, electrical, and duct connections safely.

2. Placing the New Furnace: The new unit is securely positioned, aligning it with ductwork, electrical outlets, and gas lines if necessary.

3. Connecting to Ductwork and Vents: The furnace is connected to the home’s duct system and exhaust vents, ensuring all connections are sealed to prevent leaks.

4. Electrical and Gas Hookups: Our professionals situate safe and reliable connections for gas and electricity, double-checking all fixtures to ensure compliance with safety standards.

5. Thermostat Integration: The furnace is connected to the thermostat, calibrating it for precise temperature control and efficiency.

Throughout the installation process, our technicians take care to align the system for secure and efficient operation, making necessary adjustments to ensure everything functions correctly. This detailed process highlights the importance of expertise, emphasizing the necessity for professional handling.

Common Challenges in Furnace Installation

Furnace installation can present several challenges that require skilled navigation. Our professionals are trained to identify and resolve these issues quickly and efficiently. One of the most common challenges is ensuring proper fit in spaces that may have unconventional layouts.

The challenges may include:

- Incorrect Airflow Direction: Misalignment with ducts can disrupt airflow, causing inefficient heating. Professionals use precise measurements to avoid these issues.

- Electrical and Gas Line Complications: Securing connections safely is vital, and identifying existing line issues early helps prevent potential hazards during installation.

- Ventilation Adjustments: Ensuring adequate exhaust ventilation can be challenging but is critical for dispersing combustion gases. Specialized equipment and techniques may be necessary.

- Compatibility with Existing Thermostats: Upgrading or changing a furnace may require updates or reprogramming of thermostats to maintain congruency in system operations.

Addressing these concerns involves detailed assessment and expertise, emphasizing why professional intervention is crucial. Our skilled technicians address these challenges, ensuring a seamless installation process that minimizes any potential disruptions.

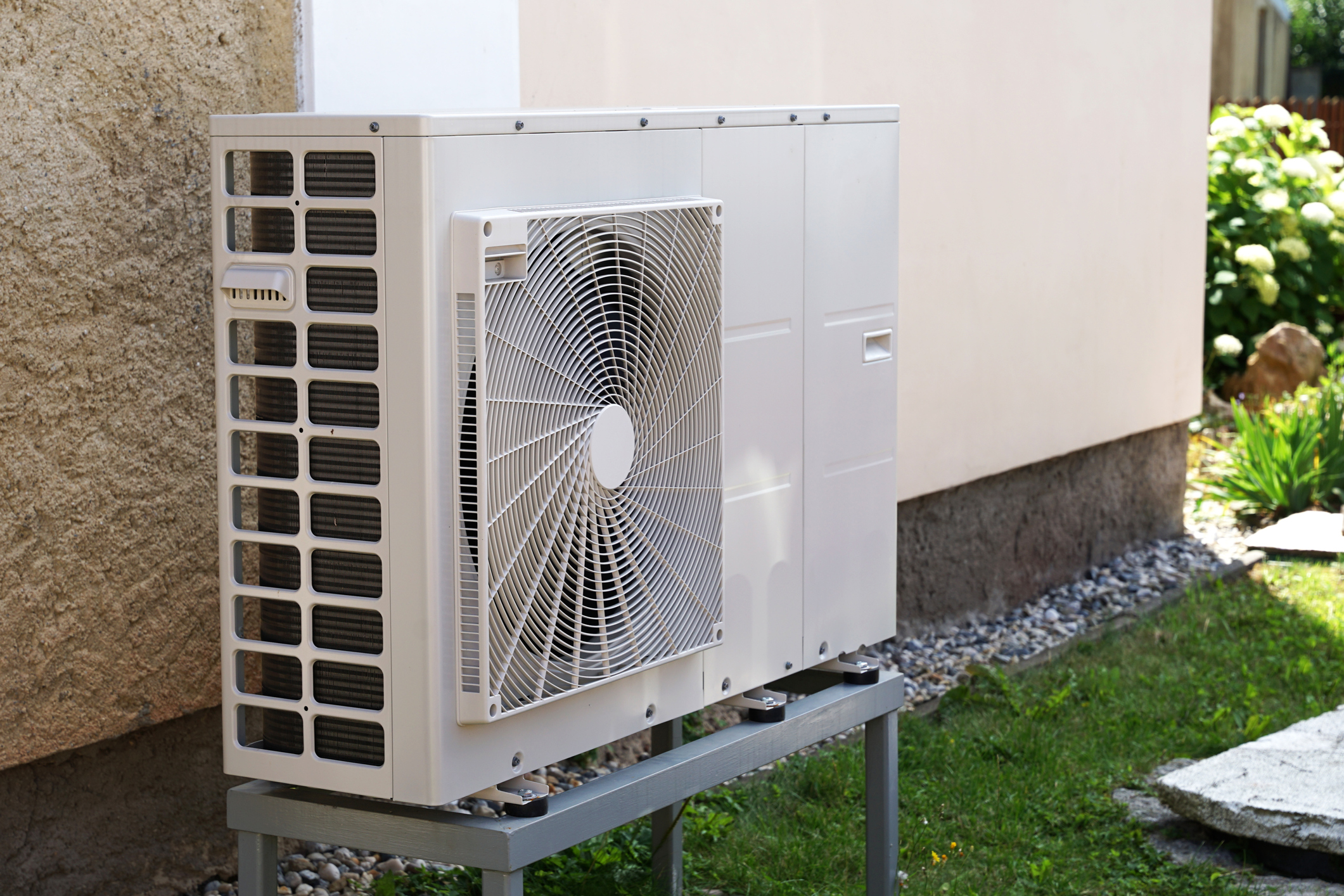

Integrating Heat Pump Systems with Your Furnace

Combining heat pumps with traditional furnace systems provides enhanced efficiency and versatility in temperature control. A dual-system setup can optimize heating by using the most efficient source based on outside temperatures.

The benefits include:

- Energy Efficiency: Heat pump systems are efficient at transferring heat during milder weather, reducing furnace usage and saving energy.

- Consistent Comfort: The dual system can automatically switch between heat pump and furnace, maintaining consistent indoor temperatures year-round.

- Reduced Wear and Tear: By sharing the load between systems, there’s less strain on each component, potentially extending the lifespan of both systems.

- Versatility: The setup offers flexibility in different environments, adjusting to varying temperature conditions efficiently.

Our technicians ensure a smooth integration of these systems, verifying compatibility with existing HVAC infrastructure. They adjust controls and configurations to optimize performance, ensuring seamless operation through all seasons.

Safety Measures and Quality Assurance

Safety is paramount during furnace installation, and our professionals follow rigorous protocols to ensure the safe and effective operation of the heating system. From initial setup to final execution, each step is observed under strict safety standards.

Key safety measures include:

- Gas and Electrical Safety: All installations comply with local codes and standards, ensuring secure connections and preventing leaks or electrical failures.

- Ventilation Assurance: Proper attachment of exhaust systems ensures combusted gases are expelled safely outside the home, preventing risks of exposure.

- Secure Positioning: The furnace is anchored to prevent movement or tilting, mitigating potential risks of disconnections or damages.

- Thorough Testing: Operational testing is conducted to ensure everything functions as intended, checking for noises, performance issues, or safety concerns.

To guarantee reliable operation, our technicians conduct detailed quality checks, identifying and rectifying any potential issues before leaving the site. Such careful attention to detail ensures that the furnace operates safely and efficiently, offering peace of mind for homeowners.

Post-Installation: Furnace Testing and Calibration

Following the installation of a furnace, rigorous testing and calibration are essential to ensure the system operates efficiently and safely. Our technicians carry out a comprehensive series of tests to verify performance and detect any potential issues.

Key testing procedures include:

- Performance Testing: The furnace’s ability to heat the living space efficiently is assessed, ensuring it reaches and maintains the desired room temperatures effectively.

- Airflow Verification: Correct duct alignment and airflow volume are checked to make sure no discrepancies might inhibit performance.

- Temperature Calibration: The thermostat is adjusted for precise temperature readings and settings to optimize the system’s energy efficiency.

- Safety Features Check: Safety mechanisms such as shutoff devices and carbon monoxide detectors are evaluated to confirm that they function properly.

Once all tests have been successfully completed, any necessary calibrations are performed. Proper calibration is critical for achieving energy efficiency and extending the lifespan of the furnace system. This thorough approach to post-installation tasks ensures that your heating system performs at its best.

Scheduling Regular Maintenance and Future Upgrades

Regular maintenance of your furnace system plays a crucial role in its longevity and performance. Routine checks help identify and solve problems early, preventing costly furnace repairs or inefficient operations.

Important aspects of regular maintenance include:

- Annual Inspections: Comprehensive checks by well-trained professionals to ensure all parts are functioning as intended.

- Filter Replacement: Keeping air filters clean and replacing them regularly to improve airflow and efficiency.

- Cleaning and Lubrication: Ensuring moving parts are lubricated and components are free from dust and debris to maintain efficiency over time.

In addition to regular maintenance, exploring opportunities for future upgrades can enhance system performance. Technological advancements often lead to newer, more efficient heating solutions that can decrease energy consumption and costs.

Considering upgrades to complementary systems, such as thermostats or ductwork, can also improve efficiency. Whether it’s implementing smart home technology or upgrading to a more efficient furnace model, staying informed about available options will enhance heating efficiency and performance.

Conclusion

Maintaining a comfortable living environment requires a reliable and efficient heating system. From selecting the best furnace and understanding the installation process to regular maintenance and strategic upgrades, each step ensures the system’s performance and efficiency.

Proper installation and integration with supplemental systems like heat pumps can bring enhanced functionality and cost savings. Addressing common installation challenges and adhering to safety standards is integral to ensuring a long-lasting and effective heating solution.

Regular maintenance and timely upgrades can greatly enhance a system’s life and functionality. By remaining proactive in the upkeep and understanding of your heating system, optimal comfort and efficiency are always within reach.

For expert assistance with furnace installation in Cherry Hill, as well as repair and maintenance, contact EnviroSafe Plumbing, Heating, Air Conditioning, Water Treatment. Our skilled technicians are committed to providing dependable solutions for your heating and HVAC needs, ensuring your home remains comfortable throughout the year.